สินค้า

รายละเอียด

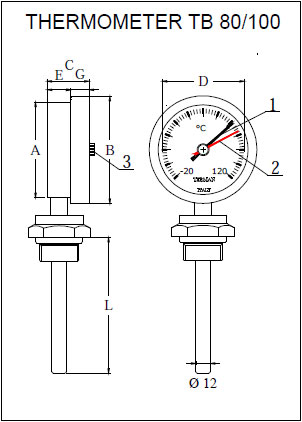

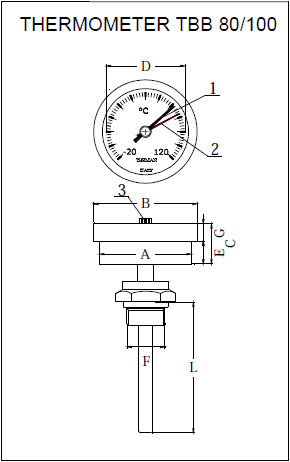

Description and general specifications.

These instruments are used to detect the temperature in the oil filled transformers and are made for outdoor mounting.

| Nominal diameter : | 80mm. or 100mm. |

| Temp. sensing system : | bimetallic spring. |

| Casing : | stainless steel AISI 304. |

| Locking clear window : | glass or polycarbonate. |

| Locking ring : | stainless steel AISI 304. |

| Maximum temp. indicating pointer : | fitted on the window and resetable with an apposite button. |

| Standard measuring range : | -20/+120°C and 0/+120°C. |

| Measuring accuracy : | 1,5% of full scale value. |

| POS. | DESCRIPTION |

| 1 | temperature pointer |

| 2 | red max temperature pointer |

| 3 | max temperature pointer reset knob |

| Dn. | A | B | C | D | E | G |

| 80 | 80 | 90 | 35 | 70 | 20 | 15 |

| 100 | 100 | 120 | 36 | 86 | 21 | 15 |

Operating instructions and maintenance.

Operating instructions :

Mounting : fix the connection on the pocket by means of a spanner. Attention don't try to tighten the connection by rotating the thermometer's head as you may damage it !

Once the connection is fixed you may need to position the dial to get the best readability. The positioning can be made by unscrewing the small screw located on the hexagonal part of the connection, rotating the thermometer head and retightening the screw.

Max temperature pointer adjustment : can be made by rotating anticlockwise the knob located on the transparent till the red maximum temperature pointer is in contact with the black pointer.

Maintenance :

No particular maintenance is required. Only, on regular basis, schedule inspections to verify correct function and calibration.

Typically a check of the precision must be done after 24 months.

In case the transparent is dirty, thus reducing the readability of the dial, you can clean it with a soft cloth, water and soap. Pay attention in case the thermometer is equipped with polycarbonate transparent as it can be scratched.

Finished product quality control tests.

Instrument calibration : carried out through thermostatic baths controlled by microprocessor based monitoring units.

The procedure varies according to instruments scale.

The calibration procedure, being the thermometer scale : 0/+120°C is made using 5 different baths set at the following temperatures :

- bath 1 = 0°C

- bath 2 = 20°C

- bath 3 = 50°C

- bath 4 = 100°C

- bath 5 = 115°C

Calibration procedure :

Step 1 : a check is carried out to see whether the temperature taken by the instrument under test differs from that taken through the sample sensor by more than the 70% of the maximum allowed instrument reading tolerance value.

This test is performed by sequentially plunging the Bimetallic Thermometer bulb into successive temperature increasing thermostatic baths : 0°C / +20°C / +50°C / +100°C / +115°C.

Step 2 : the instrument is heated until the instrument pointer exceeds by 20% the angular full scale value.

Step 3 : step 1 is repeated, but inversely.

Check of instrument mechanical protection degree : IP 55.